Plumbing Tubes

Water Reticulation

Economical

A hard drawn thin walled tube for use without bending.

Recommended for use with capillary soldered fittings in above ground installations only.

Maksal Economical Tubes for Domestic Plumbing Services.

Economical - Available in 5.5m (Hard Drawn) straight lengths only.

| Nominal Size of Tube (mm) |

Outside Diameter | Wall Thickness Economical (mm) |

Theo- retical Mass Economical (kg/m) |

Max. Working Pressure Economical (MPa) |

|

| Max (mm) |

Min (mm) |

||||

| 15 | 15.045 | 14.955 | 0.40 | 0.164 | 3.2 |

| 22 | 22.055 | 22.945 | 0.50 | 0.301 | 2.7 |

The tube is identified by black end caps, and markings every half metre "Maksal Economical"

460/0

A hard drawn thin walled tube for use without bending.

Recommended for use with capillary soldered fittings in above ground installations only.

Maksal "460/0" Tubes for Domestic Plumbing Services as per SANS 460/85 as amended 1986.

460/0 - available in 5.5m (Hard Drawn) straight lengths only.

| Nominal Size of Tube (mm) |

Outside Diameter | Wall Thickness Class 0 (mm) |

Theore- tical Mass Class 0 (kg/m) |

Max. Working Pressure Class 0 (MPa) |

|

| Max (mm) |

Min (mm) |

||||

| 15 | 15.045 | 14.955 | 0.50 | 0.203 | 4.80 |

| 22 | 22.055 | 21.945 | 0.60 | 0.360 | 3.93 |

| 28 | 28.055 | 27.945 | 0.60 | 0.460 | 3.09 |

| 35 | 35.070 | 34.930 | 0.75 | 0.719 | 3.09 |

| 42 | 42.070 | 41.930 | 0.90 | 1.036 | 3.09 |

| 54 | 54.070 | 53.930 | 1.20 | 1.774 | 3.20 |

| 67 | 66.750 | 66.600 | 1.50 | 2.751 | 3.22 |

| 76 | 76.170 | 76.030 | 1.70 | 3.537 | 3.22 |

| 108 | 108.070 | 107.930 | 2.30 | 6.807 | 3.07 |

The tube is identified by translucent end caps, and markings every half metre "Maksal SANS 460...O/D Class O"

460/1

A thin walled tube in half hard or hard condition as applicable, which should be bent only with benders which have inner and outer formers.

Recommended for use with both capillary soldered and compression fittings in above ground installations.

Maksal "460/1" Tubes for Domestic Plumbing Services as per SANS 460/85 as amended 1986.

Class 1 (Light) - available in 5.5m straight lengths only, 15 to 22mm (half hard), 28mm up to 108mm (hard drawn).

| Nominal Size of Tube (mm) |

Outside Diameter | Wall Thickness Class 1 Light(mm) |

Theore- tical Mass Class 1 (kg/m) |

Max. Working Pressure Class 1 (MPa) |

|

| Max (mm) |

Min (mm) |

||||

| 15 | 15.045 | 14.955 | 0.70 | 0.280 | 5.13 |

| 22 | 22.055 | 21.945 | 0.90 | 0.532 | 4.50 |

| 28 | 28.055 | 27.945 | 0.90 | 0.683 | 3.54 |

| 35 | 35.070 | 34.930 | 1.20 | 1.136 | 3.77 |

| 42 | 42.070 | 41.930 | 1.20 | 1.371 | 3.14 |

| 54 | 54.070 | 53.930 | 1.20 | 1.774 | 3.20 |

| 67 | 66.750 | 66.600 | 1.50 | 2.751 | 3.22 |

| 76 | 76.170 | 76.030 | 1.70 | 3.537 | 3.22 |

| 108 | 108.070 | 107.930 | 2.30 | 6.807 | 3.07 |

The tube is identified by orange end caps, and markings every half metre "Maksal SANS 460...O/D Class 1"

460/2

A hard drawn or half hard tube as applicable with excellent bending qualities.

Recommended for use with both capillary soldered fittings and compression fittings.

Maksal "460/2" Tubes for Domestic Plumbing Services as per SANS 460/85 as amended 1986.

Class 2 (Medium) - available in 5.5m straight lengths, 15 to 22mm (half hard), 28mm up to 108mm (hard drawn).

| Nominal Size of Tube (mm) |

Outside Diameter | Wall Thickness Class 2 (mm) |

Theore- tical Mass Class 2 (kg/m) |

Max. Working Pressure Class 2 (MPa) |

|

| Max (mm) |

Min (mm) |

||||

| 15 | 15.045 | 14.955 | 1.0 | 0.392 | 7.33 |

| 22 | 22.055 | 21.945 | 1.0 | 0.588 | 5.00 |

| 28 | 28.055 | 27.945 | 1.2 | 0.900 | 4.17 |

| 35 | 35.070 | 34.930 | 1.5 | 1.407 | 4.71 |

| 42 | 42.070 | 41.930 | 1.5 | 1.701 | 3.93 |

| 54 | 54.070 | 53.930 | 2.0 | 2.912 | 4.07 |

| 67 | 66.750 | 66.600 | 2.0 | 3.640 | 3.28 |

| 76 | 76.170 | 76.030 | 2.0 | 4.144 | 2.89 |

| 108 | 108.070 | 107.930 | 2.5 | 7.385 | 2.55 |

The tube is identified by brown end caps, and markings every half metre "Maksal SANS 460...O/D Class 2"

Selection of Tubing

All four classes of tubing can be used with the capillary solder system. The choice of tubing will depend on the nature of the work to be performed. If tubes are to be laid underground then Class 2 should be used.

Class 0 is recommended for all above ground work as its use would provide the maximum cost saving benefit. It is emphasized that Class 0 tubing is hard drawn and any change of direction should be made with fittings. Local annealing of Class 0 in order to produce a bend is not recommended.

When compared with traditional systems, capillary systems can realize an installation time saving of up to 70%.

SANS 460 Class 1 and 2 all have excellent bending qualities. There are various bending machines on the market and those with inner and outer formers make the best bends. Care should be taken when bending the Class 1 tube as it has a thin wall. The cheaper hand benders and springs do not perform satisfactorily on this class of tube.

Half hard tubes bent by hand should have a radius of at least 6 times the outside diameter of the tube and machine bent tubes should have a radius of not less than 3 times the outside diameter of the tube. Any deviation from the above figures could cause a restriction in the tube producing turbulent flow and the possibility of erosion corrosion.

It is most important to remember that SANS 460 Class 0 (hard drawn tube) should NOT be bent under any circumstances. Class 0 tube is ideally suited for use with capillary fittings, however, compression fittings should be avoided where possible. The use of a 90° or 45° capillary soldered elbow will provide a quick, inexpensive and neat bend.

Copper tubing, due to the very smooth bore, maintains excellent flow characteristics as there is less chance of furring than with traditional materials.

Because of copper tube’s excellent internal corrosion resistance, tube bores remain smooth and internal diameters constant, thus eliminating the need to account for bore reduction or roughening when computing friction losses as with steel piping.

Copper’s light weight facilitates shipment, fabrication and installation. When comparing steel pipe systems, weight reductions of up to 50% are afforded by copper systems. This is significant in terms of hanger requirements and dead loads imposed on supporting structural elements.

Copper is compatible with all types of piping. It is accepted practice to join copper tubing to galvanized piping provided that the copper is downstream from the galvanized pipe. Certain corrosion problems may be experienced under specific conditions if the copper tube is connected upstream.

When cutting copper tube with tubing cutters or a hacksaw, care should be taken to produce a square end and to remove the burr produced. This will remove the possibility of turbulent flow which could promote erosion corrosion.

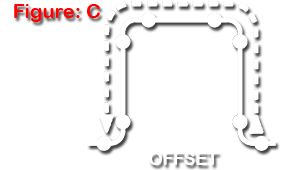

Technical Specifications & Data Design

Composition, Related Specifications & uses of Available Alloys

| Copper | |||

| Alloy | Composition | Related Specifications |

Main Uses |

| Maksal PDO Copper (Phosphorus Deoxidised non-arsenical Copper) |

Cu (+ Ag) 99.85% min P 0,015 - 0,040% |

BSS 2871 / 72 - C106 UNSC 12200 |

Standard grade of copper for general engineering applications, plumbing & heating work, ventilation & air conditioning. |

| Maksal HC Copper (Phosphorised low residual phosphorus) |

Cu (+ Ag) 99.90% min P 0,004 - 0,012% |

UNSC 12200 | Electrical purposes such as bus-bars, switchgear, slip rings, high frequency furnace coils & rotor windings in large generators |

Physical Properties of Alloys (metric units)

| KEY | H - Hard | ½ - H - Half Hard | A - Annealed | HT - Heat Treated |

Thermal Conductivity is the quantity of heat (W) transmitted in unit time (s) due to a unit temperature gradient (°C ) over unit area (m²> and in direction normal to the surface. Resistivity is the resistance in ohms of a block of unit length (m) and unit cross-sectional.

Hydraulic Characteristics of Smooth-wall Materials

The hydraulic character of a piping material, determined by the size and smoothness of its bore, enables it to deliver water at sufficient pressures to overcome static head and operate fixtures, appliances and equipment. When comparing two smooth-wall materials, such as copper and polypropylene, internal diameter becomes the critical factor in evaluating hydraulic performance.

Table 1:

Comparison between 460/0 Copper tube (Cu) and Polypropylene tube (PP) showing area of bore, percentage difference and flow rates.

| Nominal Tube Size |

Ave W.T. |

Ave W.T. |

Area of Bore in mm2 |

Copper Greater Area % |

Flow Rate l/m at 2.5m/sec |

Pressure drop in kPa per 10m length |

|||

| PP | Cu | PP | Cu | PP | Cu | PP | Cu | ||

| 15 | 1.8 | 0.5 | 102 | 154 | 50 | 15.5 | 23.0 | 88.0 | 55.0 |

| 22 | 2.7 | 0.6 | 216 | 346 | 60 | 32.5 | 52.0 | 56.5 | 33.5 |

| 28 | 3.4 | 0.6 | 353 | 564 | 59 | 53.0 | 84.5 | 41.0 | 24.5 |

Table 2:

Comparison of flow rate using the same pressure drop values for the same nominal tube size. The pressure drop values used are the same as those for copper tube in Table 1.

| Nominal Tube Size |

Pressure drop in kPa per 10m length |

Flow Rate I/m | |

| PP | Cu | ||

| 15 | 55.0 | 11.5 | 23.0 |

| 22 | 33.5 | 24.0 | 52.0 |

| 28 | 24.5 | 39.0 | 84.5 |

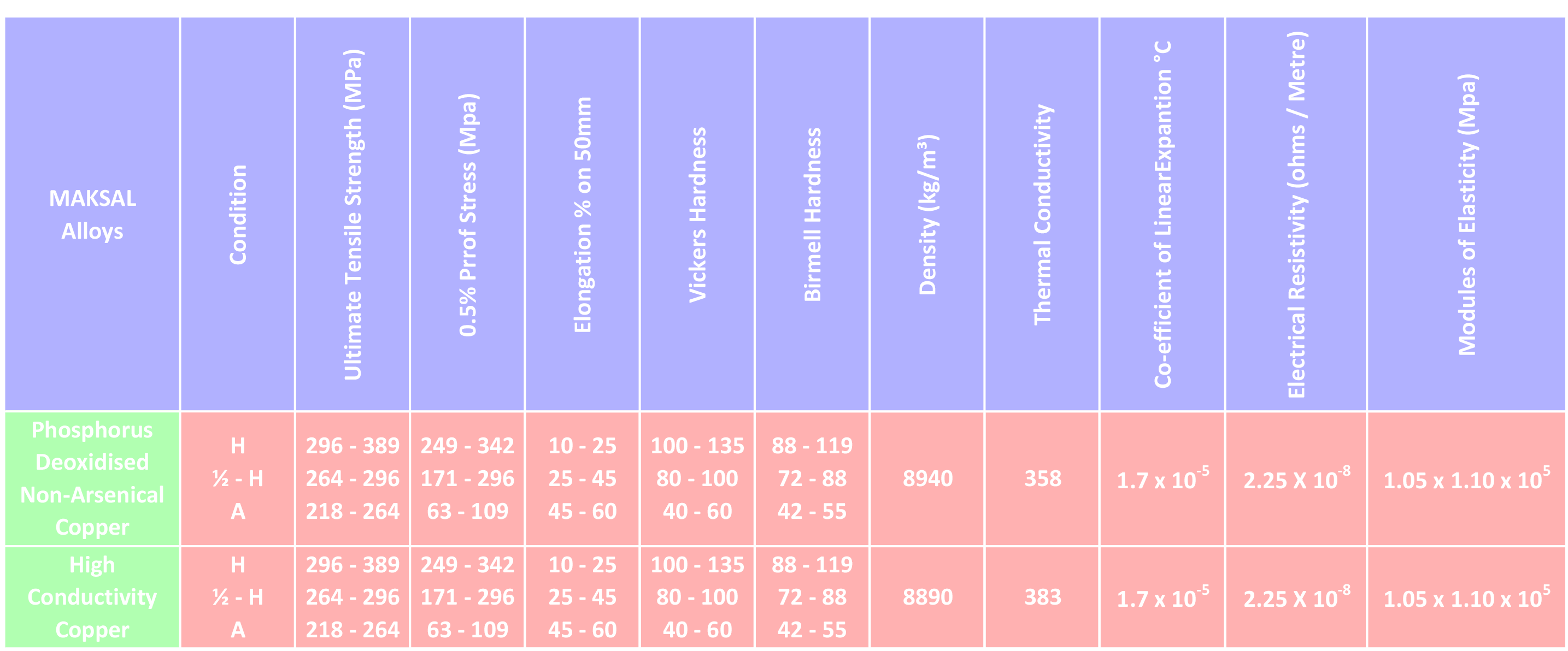

Today there is a tendency to use pipes made from plastic-type materials. These pipes usually have thicker walls than conventional copper tubes, so their internal diameters or bores are considerably smaller. It is after all the bore of the pipe that is important when considering volumes, flow rates and velocities and not the outside diameter of the pipe.

Just how much the bore does vary is clearly shown in the tables above. it is therefore very important to note that one type of pipe cannot necessarily be directly substituted for another even though they have the same outside diameter.

When using plastic pipes, it would be a good rule of thumb to install one nominal size larger than would normally be specified in steel or copper.

Copper offers substantially greater bore areas than plastic for the same outer diameter of pipe. Example as per illustration above: 22mm outer diameter copper pipe offers 60% greater bore area than 22mm outer diameter plastic pipe.

Thermal Contraction & Expansion SANS 460 Tubing

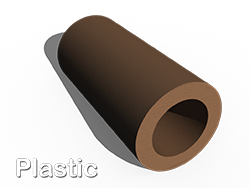

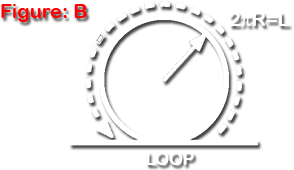

Thermal Contraction and expansion in pipelines should be allowed for by expansion loops or bends, the dimensions and spacing of which should preferably be such that combined stresses are kept below the fatigue limit.

Figure 1: Expansion Loops and Offsets

Radius of Coiled Expansion Loops (For configuration shown in Figures 1A & 1B)

| Expected Expansion (mm) |

Radius "R" for Tube Sizes Shown (mm) | ||||||||

| 15 | 22 | 28 | 35 | 42 | 54 | 67 | 76 | 108 | |

| 12.7 | 203 | 229 | 279 | 305 | 330 | 381 | 406 | 457 | 508 |

| 25.4 | 279 | 330 | 381 | 432 | 457 | 533 | 584 | 635 | 737 |

| 38.1 | 355 | 406 | 457 | 508 | 559 | 635 | 711 | 762 | 889 |

| 50.8 | 406 | 482 | 533 | 584 | 635 | 737 | 813 | 889 | 1041 |

| 63.5 | 457 | 533 | 609 | 660 | 737 | 838 | 914 | 1016 | 1143 |

| 76.2 | 482 | 584 | 660 | 737 | 787 | 914 | 1016 | 1092 | 1270 |

| 88.9 | 533 | 635 | 711 | 787 | 864 | 991 | 1092 | 1194 | 1372 |

| 101.6 | 558 | 660 | 762 | 838 | 914 | 1041 | 1168 | 1270 | 1448 |

Developed Length of Expansion Offsets (For configuration shown in Figure 1C)

| Expected Expansion (mm) |

Length of Tube Sizes Shown (mm) | ||||||||

| 15 | 22 | 28 | 35 | 42 | 54 | 67 | 76 | 108 | |

| 12.7 | 1270 | 1498 | 1701 | 1879 | 2032 | 2311 | 2590 | 2819 | 3251 |

| 25.4 | 1778 | 2108 | 2387 | 2641 | 2870 | 3276 | 3657 | 3987 | 4572 |

| 38.1 | 2184 | 2565 | 2921 | 3225 | 3505 | 4013 | 4470 | 4851 | 5588 |

| 50.8 | 2514 | 2971 | 3378 | 3733 | 4064 | 4648 | 5156 | 5638 | 6477 |

| 63.5 | 2819 | 3327 | 3784 | 4191 | 4546 | 5207 | 5765 | 6209 | 7239 |

| 76.2 | 3098 | 3632 | 4140 | 4572 | 4978 | 5689 | 6324 | 6980 | 7924 |

| 88.9 | 3327 | 3937 | 4470 | 4953 | 5384 | 6146 | 6832 | 7442 | 8559 |

| 101.6 | 3556 | 4216 | 4775 | 5283 | 5740 | 6578 | 7315 | 7975 | 9169 |

The co-efficient of linear expansion of copper tubing is 0.0166 mm/metre C between O °C and 100°C. Example: For a 60°C rise in temperature between these limits, the linear expansion would be 1mm per metre and between 20°C and 60°C the linear expansion would be 0.67mm per metre.

Holderbats - Tube Supports and FixingsThe correct selection and installation of tube supports is an important factor in the design of any system. Incorrect use or selection can lead to serious problems in relatively short periods of time. A number of factors should be taken into consideration before selection:

Dissimilar MetalsThe use of steel or galvanised materials should be avoided in humid atmospheres or in situations where condensation is likely. In these conditions corrosion of the pipe support could take place. If the use of these materials can not be avoided, they should be totally insulated from the copper pipe. This can be effected by the use of wood, plastic or rubber. Ideally the use of brass or copper supports would be recommended.

Allowance for ExpansionAll support brackets or holderbats should be fixed so as to allow free movement of the pipe within the fixture. This is to allow for the expansion and contraction of the pipes during operation of the system and is especially important on hot water lines.

PositioningAttention should be paid to the positioning of the supports. As a general rule, a holderbat or support should be placed at least 500mm away from a change of direction fitting i.e. tee or elbow.

Don'tsThe use of nails, wire etc. as an alternative to the correct fixing should be avoided at all times. This can lead to premature failures due to several factors.

Golden RuleDo not over tighten, allow the tube to expand without restriction and beware of dissimilar materials.

| Tube Size (mm) |

Intervals for Vertical Runs (metre) |

Intervals for Horizontal Runs (metre) |

| 15 | 1.9 | 1.3 |

| 22 | 2.5 | 1.9 |

| 28 | 2.5 | 1.9 |

| 35 | 2.8 | 2.5 |

| 42 | 2.8 | 2.5 |

| 54 | 3.9 | 2.5 |

| 67 | 3.9 | 2.8 |

| 76 | 3.9 | 2.8 |

| 108 | 3.9 | 2.8 |

Pressure Ratings

Working Pressures are based on a working stress in the copper tube wall of 72MPa which provides for a factor of safety on the ultimate strength of between 5.24 & 7.1.

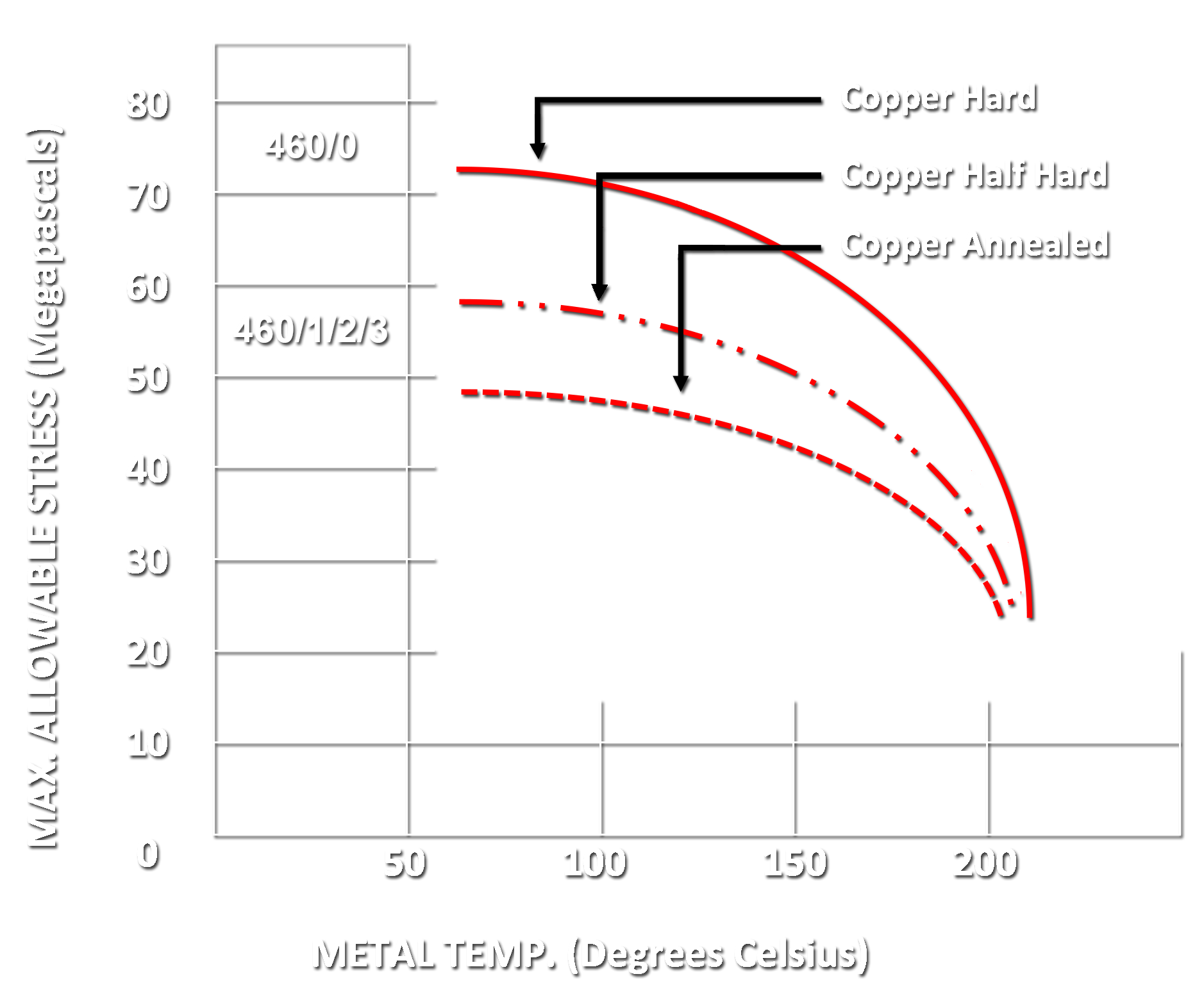

Working Pressures (Temp. exceeding 65°C)For working temperatures exceeding 65°C the safe working stress can be determined from the chart.

Having established the safe working stress at a given temperature the safe working pressure for a tube of specific dimensions can be calculated from the following formula:

| P | = | 2ft |

|

|

||

| D |

P = safe working pressure

f = safe working stress in tube wall MPa (from chart)

t = tube wall thickness (mm)

D = tube outside diameter (mm)

The safe working stress for a fully annealed tube at 150 C is found from the chart to be 34 MPa. For a tube of this quality, 15.00mm o.d. by 0.50mm thick, the safe working pressure is thus:

| P | = | 2 x 72 x 0.50 | = 4.8MPa |

| 15 |

If brazing tube and fittings, the temperature required to melt the filler material (650°C - 750°C) is sufficient to fully anneal the tube. Pressure ratings should therefore be calculated using the formula as shown above.

The allowable internal pressure for any copper tube in service is based on the Barlow formula for thin-walled, hollow cylinders used in the ASME B31 Code, for Pressure Piping.

The value of S is the allowable design strength for continuous long-term service of the tube, as determined by the ASME Boiler and Pressure Vessel Code, Section 1 - Material.

Allowable stresses for annealed and drawn temper copper tube are shown in the table below. They are only a small fraction of copper s ultimate tensile or burst strength. In system design, joint ratings must also be considered, as the lower of the two ratings (tube or joint) will govern the installation. The rated joint strength in soldered tube systems often governs design. However, annealed ratings must be used in brazed systems since the brazing operation may anneal the tube near the joints.

| P | = | 2stm |

| D - 0.08tm |

P = allowable pressure

S = allowable stress

t = wall thickness

Dm = outside diameter (mm)

| Temperature (°F) | Allowable Stress (psi) | |

| Annealed | Hard Drawn | |

| 100 | 6000 | 10300 |

| 150 | 5100 | 10300 |

| 200 | 4900 | 10300 |

| 250 | 4800 | 10300 |

| 300 | 4700 | 10000 |

| 350 | 4000 | 9700 |

| 400 | 3000 | 9400 |

| Conversion Factors | |

| STRESS: | Psi x 0.006895 = MPa MPa x 145.04 = Psi |

| TEMPERATURE: | F = [( F-32)/1.8] C C = [( C-1.8)/32] F |

Copper Underground - It's Resistance to Soil Corrosion

In an attempt to categorise the nature and extent of the corrosion of copper pipe underground, studies by both the National Bureau of Standards in the States and the BNF Metal Research in the UK Classified the soils according to type.

An indication as to how various piping materials would behave when in these soils can therefore be obtained by matching the soil under question with the one described in the actual test. It should be borne in mind that various factors such as drainage, acidity and alkalinity as indicated by pH value, humus content and sulphate and chloride contents all influence the rate of corrosion. The worst case of corrosion occurred in soils with very poor drainage, whereas in well drained soil corrosion was always slight. It should be pointed out that in all cases other materials tested, lead, steel and cast iron, had higher pitting corrosion rates and in most cases higher averaged rates than copper.

| Soil Type | pH | Years Buried |

Average Corrosion Rate (mm) |

Maximum Pitting Rate (mm) |

| Cinders | 8 | 9.2 | 0.04 | 0.15 |

| Wet Acid Peat | 4.2 | 10.5 | 0.007 | 0.02 |

| Moist Acid Clay | 4.6 | 10.5 | 0.005 | 0.04 |

| Made Up Ground | 9.8 | 0.0003 | 0.002 | |

| Dry Acid Sound | 5.1 | 11.0 | 0.0002 | 0.0002 |

| Moist Normally Clay | 7.2 | 11.0 | 0.0002 | 0.0002 |

| Chalk | 5.4 | 11.0 | 0.0001 | 0.0002 |

| Slightly Acid Sand | 6.2 | 11.0 | 0.0001 | 0.0002 |

It would appear that where serious corrosion occurs, it is not due to any one characteristic of the soil or climate, but to a combination of high sulphate and/or chloride content with poor drainage and considerable moisture capacity and a moderate or heavy rainfall.

Soils containing a large proportion of organic matter and moisture such as tidal marsh, peat and muck possess the combination of properties mentioned above as particularly conducive to corrosion. Cinders when left moist are highly corrosive, either because of the very aggressive sulphide in them or possibly owing to galvanic action between the carbon in them and copper.

In the test conducted by both the BNF and the NBS, copper proved to be the most satisfactory material.

A simple calculation shows that for all but the most aggressive soils, class 2 copper tube would provide excellent service.

Galvanic CorrosionMany existing domestic water systems provide excellent examples of mixed metal systems. Copper hot water cylinders, zinc coated steel pipes and brass taps. There is no record of serious galvanic corrosion problems from such systems largely as a result of the water quality and the favourable anode/cathode area ratio. An additional corrosion mechanism falling within the realms of galvanic corrosion should be considered. In a mixed metal plumbing system it is a well documented fact that copper ions taken into solution from the copper portions of the system can cause corrosion of the downstream zinc coated system. What happens is that the copper ions plate out on the less noble zinc and once plated out form a localised cathode of an active galvanic cell. However, having made such a statement the practical situation is somewhat different. Reef waters - our electrolyte - at the present pH and TDS ranges quickly forms an oxide layer in the copper portion of the system which effectively prevents copper ions entering the solution and in addition forms a protective scale on the zinc coating preventing the plating out of the copper ions. It should be emphasised, however, that new mixed metal systems are most susceptible to this form of corrosion and it is strongly recommended that copper tubing always be installed downstream to zinc coated steel in new installations.

The high incidence of corrosion failures in zinc coated steel systems, however, raises a number of questions when replacement is considered. Copper tubing can be used to replace any portion of a failed system which has been in service a number of years as exposed zinc metal is unlikely to be present. Possible subsequent failure of the remaining old installation cannot be attributed to the installation of the copper and the advisability of partial replacement of a system should receive careful consideration.

Copper and zinc feature in many modern building applications. Copper and galvanised sheeting for roofing purposes and brass and copper for fasteners. Zinc sheets should never be fixed with copper nails nor should brass screws be used to attach aluminium plates. Copper roofs should not drain into zinc or galvanised gutters for the same reason that zinc coated pipe should not be installed downstream from copper tubing.

An electro-chemical potential almost always exists between two dissimilar metals when they are immersed in a conductive solution, if two dissimilar metals are in electrical contact with each other and immersed in a conductive solution, a potential results which electropositive member (the cathode).

Although we often refer to the metals being immersed in the electrolyte we must not forget that the same conditions exist when the electrolyte is contained in a tube or a pipe.

Mixed Materials

Copper metals are almost always cathodic to other common structural metals such as steel, aluminium and zinc. When steel, aluminium or zinc is put in contact with a copper metal, the corrosion rate of the steel, aluminium or zinc increases where as that of the copper metal decreases. When copper metals are coupled to the normal grades of stainless steel variable behaviour is experienced; copper metals may be either anodic or cathodic to the stainless steel depending on conditions of exposure.

Copper metals usually corrode preferentially when coupled with high nickel alloys, titanium or graphite.

When Copper is alloyed with zinc to form the brasses or aluminium to form the aluminium bronzes, the potential is moved towards the anodic (more electro negative) end of the range; additions of tin to form the bronze alloys or nickel to form the cupro-nickels move the potential towards the cathodic (less electro negative) end. Galvanic corrosion between two metals is seldom a significant problem because the difference in potential is small.

The Galvanic seriesThe galvanic series of metals and alloys provides a more practical means of predicting the corrosion behaviour of dissimilar metals but should not be used without the consideration of the conditions present in the system. Galvanic series generally refer to metals and alloys under specific conditions.

Table 1, lists a galvanic series of metals and alloys valid for dilute solutions such as seawater and weak acids. The metals that are grouped together may be coupled to each other without significant galvanic damage.

However, connecting metals from different groups leads to damage of the more anodic metals; the larger the difference in galvanic potential between groups the greater the corrosion is likely to be.

Table 1: Galvanic Series in seawater

| Anode End | Muntz Metal |

| Magnesium | Manganese Bronze |

| Magnesium Alloys | Navel Brass |

| Zinc | Cartridge Brass |

| Galvanised Steel | Admiralty Metal |

| Aluminium | Aluminium Bronze |

| Cadmium | Red Brass |

| Low-carbon Steel | Copper |

| Wrought Iron | Silicon Bronze |

| Cast Iron | Copper Nickel 30% |

| Ni Resist | Nickel (Passive) |

| Type 410 Stainless Steel (Active) | Inconel (Passive) |

| 50Pb-60Sn Solder | Monel |

| Type 304 Stainless Steel (Active) | Type 304 Stainless Steel (Passive) |

| Type 316 Stainless Steel (Active) | Type 316 Stainless Steel (Passive) |

| Lead | Silver |

| Tin | Gold |

| Nickel (Active) | Platinum |

| Inconel (Active) | Cathodic End |

Freezing

Although variations in climatic temperatures are not as extreme in South Africa as they are, for example, in certain northern European countries, there are areas in this country where burst pipes due to winter freezing are not uncommon.

According to London-based metallurgical consultants, Clifford Breckon Limited, the layout of the plumbing system, particularly with regard to such things as the position of the fittings and the point of exposure to the lowest temperature, will affect the tendency of the system to freeze.

It is preferred practice not to lag each pipe individually in the roof, but to place the pipes below the ceiling lagging, which would protect the pipes from any draughts. At the same time, the warm air rising from the room below would be trapped in the space between the ceiling and the lagging where the pipes are situated.

Freezing itself does not necessarily mean that the pipes will burst. It is not the distension of the tubes by the ice which will cause a burst, but rather its distension by the water under pressure which causes the problem. Bursting, for example, does not occur at the first part to freeze, on the contrary, bursting invariably occurs where the water is still present as a liquid and usually, therefore, one of the last parts of the system to actually freeze. The pressure to produce bursting is generated by the change from water to ice and if the coldest point is in the middle of a straight length so that a plug of ice is first formed at this point with say, a fitting or stop tap at one side, then the chances are that the plug of ice will be moved along the tube by the pressure rather than a pressure build-up occurring.

The effect of pressure is to depress the freezing point slightly, so that under a mild frost nothing would happen in the case of a smooth bore copper tube. On the other hand, of course, if the first point to freeze was where there was a fitting, or stop cock, and there was a length of pipe which was subjected to freezing temperatures with a solid closure at the far end, then eventually the pressure build-up would be such as to burst the tube. Under these conditions the relative bursting point of a galvanized iron pipe will be higher than that of a corresponding copper pipe, so that marginally less failures might occur with galvanised iron. On the other hand, the chances of a plug of ice moving in a galvanized iron pipe is remote, so that from this point of view more failures would be likely to occur with galvanized iron than with copper.

Summarizing the position, you have to emphasize that layout and exposure conditions are extremely important and that the cause of bursting is pressure generated by the conversion of water to ice and that this pressure can be transmitted hydraulically in the usual way. The freezing itself is not a danger, except for the generation of this pressure, it is not the distension of the of the tube by the ice but rather the distension of the tube by water under pressure which causes the problem. Depending on the exposure conditions, bursts are less likely to occur under some circumstances with copper because of the smoothness of the bore.

General Considerations

Research into the mechanism of pitting corrosion has been undertaken by the copper industry in many countries of the world. Pitting occurs typically in cold, aerated, hard, organically pure waters from deep wells or boreholes and not in surface waters as generally used.

Borehole water and surface water can vary widely throughout the different areas of South Africa. The only regulations relating to potable water at present are those of the SANS which are classified as guidelines/recommendations and cover the health aspect rather than a corristivity with relation to any type of tubing used for reticulation of the water. Not all borehole waters are corrosive to copper or other types of available tubing, but a good general rule would be to have the water tested before selecting the type of tube to be used to ensure maximum durability of the installation.

Concrete & ChasingConsiderable research has been conducted on the effect of concrete on the corrosion of copper tubes and to quote from an International Copper development Council report: technical report Number 201 "copper tubes in ordinary Portland cement or concrete made with it do not suffer corrosive attack, but from an uniform adherent oxide layer. Similarly concrete with calcium chloride added has no corrosive effect even when the set concrete is kept intermittently or permanently wet.

An element often overlooked when considering the coupling of dissimilar metals is carbon. Practically all metals when coupled to carbon under the correct conditions would become anodic.

It would therefore be advisable to guard against the use of copper with ash bricks or cinders when used as backfill or the contamination of sand or concrete mix with ash from on-site open fires.

Under these conditions, with a strong electrolyte present, active galvanic cells could be set up and localised corrosion of the copper tube could take place resulting eventually in failure

Capillary Soldered Joints

Since the introduction of thin walled copper tubes in the early 80's, this method of joining copper tubes has become the most widely used. This has been due to several factors:

- Its ease of fabrication.

- No expensive and heavy tools required.

- Cost effective - up to 70% saving on time and labour.

- Excellent mechanical properties.

- Non-bulky fittings makes for a very compact system.

When installed correctly the capillary joint offers one of the strongest system joints available with a shear strength of up to 60MPa (600 Bar). This gives the system the ability to withstand high degrees of expansion, contraction and vibration.

SolderingThe use of the correct solder is extremely important if the completed joint is to maintain the required mechanical properties throughout its working life. Acid or resin core solders should not be used. These normally contain lead which should be avoided for health reasons and they do not have the required shear strength to withstand contraction and expansion.

Solders recommended for plumbing installations are covered by the SABS 24-1971, amended 1987, or DIN 1707 specifications.

Maksal 97/3 (97% Tin, 3% Copper). This is the most widely used of the solders, and it is the most cost effective and readily available.

Soft solder has a melting point of 240°C. Their use prevents annealing (softening) of the tube and fitting during heating and eliminates the possibility of the formation of deleterious films which could under certain circumstances lead to pitting corrosion.

NOTE:- All solders containing Lead should not be used.

- Resin Core or Acid Core solders should not be used.

The correct amount of solder is important. A guide to minimum quantities is shown in the table below:

Table 1:| Pipe OD (mm) | 15 | 22 | 28 | 35 | 42 | 54 | 67 | 76 | 108 |

| Length of Solder 2mm Diameter |

15 | 40 | 50 | 100 | 160 | 230 | |||

| Length of Solder 3mm Diameter |

25 | 50 | 75 | 105 | 165 | 195 | 455 |

The function of the flux is fourfold in ensuring the successful completion of a capillary soldered joint. The selection of a correct flux is therefore most important. A satisfactory flux will perform the following functions during soldering:

- It will remove residual traces of oxide.

- It will prevent the reformation of oxide.

- It will promote "wetting" and assist capillary action.

- It will readily flow out of the joint as solder flows in.

- The flux should be "self-cleaning".

- The flux should be easily applied.

- The flux should be water based and easily flushed out.

- The flux should contain NO ammonia.

- The flux should withstand temperatures above 240°C.

A most suitable flux which meets all the above criteria and is highly recommended is Maksal EVERFLUX.

NOTE:Self-cleaning fluxes will not remove dirt, plaster, tape glue etc. These must be removed mechanically with wire wool or emery cloth. Keep the lid on flux containers when not in use. Dirty or contaminated fluxes should be discarded to prevent poorly soldered joints. Good practice dictates that what is cleaned, fluxed and assembled today is soldered today. If the joint is allowed to stand overnight without soldering, it should be taken apart, re-cleaned - removing old flux and re-fluxed before soldering.

Heat SourcesAs the recommended soft solder has a melting point of ±240°C the soldering of all capillary joints requires only a soft non-localized flame such as that produced by LPG Gas.

The use of Oxy-acetylene is NOT RECOMMENDED. The heat from Oxy-acetylene is too severe and concentrated, especially when using thin walled copper (SANS 460/0) grades. This can cause overheating, burning of the flux, annealing and in more severe cases melting of the tube and fitting.

Various electrical resistance soldering machines are also available and can have several advantages when used in areas such as:

- Thatched roofing spaces.

- In close vicinities to combustible materials.

- Workshops, for prefabrication use.

- The heat should be uniform, not concentrated.

- Heat should be sufficient but not too hot.

- Flame size should not be excessive.

The soft soldering of capillary joins can be split into two methods, one for smaller sizes up to 54mm diameter and one for sizes above 54mm diameter.

Soldering of these sizes can be achieved in any position with only one point of entry of solder into the joint.

- Cut the tube to the required length. The use of a tube cutter is recommended rather than a hacksaw as a square cut ensures full penetration of the pipe into the fitting. Ensure all burrs are removed and the tube end is reamed if required to prevent water flow restrictions.

- Clean tube end and fitting, if required, to remove any dirt, plaster, tape glue etc. by means of a ring brush, wire wool or emery cloth.

- Apply Maksal Everflux to the outside of the tube for a length at least equal to the depth of the fitting. It is good practice to also apply flux to the inside of the fitting. The flux should be used sparingly, ideally applied by use of a small brush rather than a finger, nail, stick etc. After fluxing assemble joint ready to solder.

- The amount of solder used to fill the joint is important if leaks are to be avoided and strength maintained. To assist, refer to Table 1, which shows recommended lengths of solder to be used for the different joint sizes. It is recommended that this table is used and the solder bent at right angles and used as a guide to ensure sufficient solder is applied to each joint whilst also avoiding wastage.

- Apply the flame to the assembled joint concentrating the heat at the centre of the fitting rather than the tube. CAUTION: DO NOT MELT THE SOLDER WITH THE FLAME!

- The tube and fitting should be heated sufficiently to melt the solder when applied without the use of the flame. The correct temperature can be tested by removing the flame and offering the solder to the mouth of the joint. Take care not to overheat the joint. An indication of overheating is when the flux turns black. If this occurs remove fitting, clean pipe and fitting and re-solder. Ensure sufficient solder has been applied by the appearance of a visible fillet.

- After a short cooling period, slightly longer for brass fittings than copper, remove any excess residual flux with a damp rag. This gives the joint a clean, neat and professional appearance. It also stops the area around the joint, which has been in contact with the flux, turning green.

- Use only the recommended flux and solders.

- Cut the tube end square and deburr.

- Apply flux sparingly on tube and fitting.

- Measure correct amount of solder.

- Do not melt solder with the flame.

- Do not overheat the joint.

- Check visually for solder fillet.

- Wipe off excess flux after soldering.

Good practice dictates whenever possible the completed system should be fully pressure tested before being closed up. Always flush the system as soon as possible after completion to remove flux residues from inside the pipes. The recommended use of water soluble fluxes such as Maksal Everflux will assist in the ease of the operation. If a system is to be inoperative for any extended period after installation, it is recommended that it be completely drained after testing and flushing and left empty of water. Capillary fittings with short sockets should not be used for soft soldering. Standards laid down by SABS 1067, Part 11 and equivalent to international standards are as follows:

Table 2:

Diameter

| Tube OD | Socket Length | Tolerance ± |

| 15 | 12 | ±1.4 |

| 22 | 17 | ±1.6 |

| 28 | 20 | ±1.6 |

| 35 | 25 | ±2.0 |

| 42 | 29 | ±2.0 |

| 54 | 34 | ±2.0 |

| 67 | 35 | ±2.5 |

| 76 | 36 | ±2.5 |

| 108 | 50 | ±2.5 |

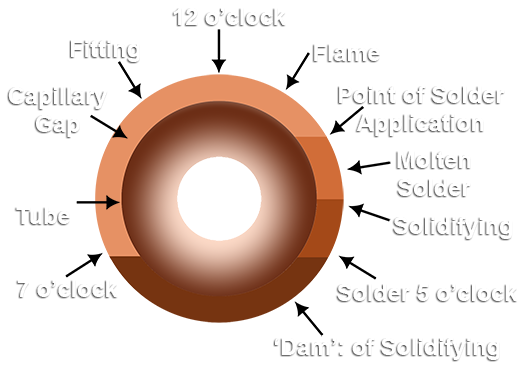

Figure 1:

Schematic Stages of Large Diameter

Soldered Capillary Joint

Sizes above 54mm

The successful soft soldering of these large diameter joints requires greater skill and specialised techniques. Soldering of these sizes can also be achieved in any position if the correct procedure is followed.

- Correct joint preparation is important if the joint is to be made successfully. The basic steps of joint preparation (refer to steps 'a' to 'd' page 18) also apply to larger sizes and should be followed every time.

- Commence by pre-heating the tube until the flux at the mouth of the joint begins to run, then transfer the flame to the fitting. Continue pre-heating the fitting ensuring the heat is applied evenly and uniformly around the fitting. Finally bring the torch to about the "7 o'clock" position, test and heat until the solder melts from the heat of the tube. Whilst preventing the solder from running out the remaining portion is being soldered. Continue up from the "5 o'clock" position keeping the flame slightly ahead of the solder and ensuring the "Dam" remains solid until the "12 o'clock" position is reached.

Move the flame back down the opposite side and following the same procedure apply the solder from the "7 o'clock" position, up to, and slightly overlapping the "12 o'clock" position. Finally remove the flame and continue applying the solder into the joint until it is completely full and will accept no more solder. Once the solder has solidified, the joint area should be wiped with a damp rag to remove any excess flux. (Refer to section on page 18 & 19 for proper procedures).

Brazed joints

The brazing of capillary fittings to SANS 460 Class 0, copper tube on sizes below 54mm OD and SANS 460 Class 1 copper tube on sizes below 35mm OD, is not recommended by Maksal.

Brazed joints would normally be used only where operating service temperatures are above 150°C.

Unlike solder with a melting point of ±240°C, brazing materials melt in the range of 600°C to 750°C. Consideration of this must be taken when designing a system as these temperatures will anneal the tube and fitting. Pressure ratings should therefore be calculated as for annealed tubing and care taken to avoid mechanical damage and consideration be given to adequate and correct tube supports.

There are two types of filler materials in normal use. These are alloys containing silver and alloys containing phosphorus. Fluxes are not normally required when joining copper to copper only when joining copper to brass or cast bronze fittings. Check with recommendations of the filler material manufacturer for the correct flux and application.

The various steps of joint preparation and application of the filler material are the same as for the large size soldered joints.

It is recommended that a slightly reduced flame be used i.e. Excess fuel.

As with soldering the brazing filler material MUST flow into the capillary joint and fill the capillary gap for the full depth of the socket. It is extremely BAD practice to apply only a "fillet" weld around the mouth of the fitting. It is advisable to allow the fitting to cool naturally after brazing. Brass or bronze cast fittings should never be cooled quickly by means of water.

The heat source for brazing would normally be Oxy-acetylene to provide the required temperature. It is important that this flame does not remain on the same point and damage the joint but kept in motion over the section being brazed.

Compression fittings

Brass compression fittings, to avoid corrosion problems, should be dezincification resistant. It is not recommended by Maksal that they be used in conjunction with SANS 460 Class 0, hard drawn tube, but only on the half hard classes i.e. 460/1 - 460/2 tubing. These fittings rely on the compression of the brass olive onto the tube. It is BAD practice to either solder the olive or fitting into the tube or apply any PTFE tape or hemp to the fitting. DO NOT over tighten the cap nuts.

Tips on Good Workmanship

Maksal SANS 460/0 hard drawn copper tube together with the capillary solder system is in many cases the most cost effective and the system which offers the highest reliability.

- NEVER use Acid core, Resin core or Lead solders.

- NEVER melt the solder with the flame.

- NEVER overheat a tube and fittings. Always test by removing the flame and applying the solder. When at the correct temperature the solder will be drawn into the joint.

- WHEN soldering a tube to a tap first remove the washer.

- WHEN male or female iron to copper fittings are to be used it is good practice to solder the joint first before screwing in the fitting. This prevents burning of the PTFE tape or hemp used on the thread.

- ALWAYS feed the solder from the bottom up to the one side and then up the opposite side and not down from the top when soldering large size joints above 54mm.

- ALWAYS use Maksal EVERFLUX for best results.

- ALWAYS solder joints the same day you flux.

- ALWAYS use flux sparingly - apply with a small brush.

- ALWAYS wipe off residual flux after soldering.

- ALWAYS flush system on completion of soldering.

- Discourage the practice of annealing 460/0 tube in order to bend especially when a cross- over is required.

- Discourage the use of fittings with short socket depths.

- A joint cannot be re-heated and pulled apart if there is water in the tube.

- Repairing a nail hole: Cut a slip coupling in half (lengthwise), clean off burrs, apply flux and place over hole, hold in place with thin wire, heat and apply solder feeding around full circumference.

Remember when making cost comparisons the only effective comparison combines all the costs of the system, tube, fittings, extras and labour. One should never cost and compare individual items e.g. Tube alone.

SERVICE:To assist plumbers and specifiers, Maksal conducts training sessions on the correct use of copper tubing. Major points covered are:

- Specifications for Copper Tube

- Performance of Copper Tube

- Joining of Copper Tube

- The Capillary Solder System

Maksal™ will also assist in other areas such as specifying and site inspections covering materials and workmanship.

OPTIMUM RESULTS:It is recommended to use the integrated Maksal system of:

- Maksal Copper Tube

- Maksal Everflux

- Maksal Fittings

- Maksal Solder

For optimum results.